The American National Standards Institute (ANSI) plays a crucial role in shaping safety standards across various industries by providing a framework for Standards Developing Organizations (SDOs) to create and maintain standards. While ANSI does not directly develop standards itself, its endorsement of standards developed by SDOs lends credibility and influence to these guidelines. This article explores the significance of ANSI standards, particularly in relation to workplace safety and their alignment with OSHA regulations.

ANSI and Workplace Safety (Video link: https://vimeo.com/575126391)

ANSI standards are instrumental in promoting safety and consistency in workplace environments. Unlike OSHA regulations, which are mandatory and enforceable by law, ANSI standards are voluntary. However, adherence to ANSI standards is highly encouraged as they are often adopted by regulatory bodies like OSHA, thereby influencing legal requirements. This dual approach—complying with both mandatory OSHA regulations and voluntary ANSI standards—enhances safety measures, reduces injuries, and fosters a more secure workplace environment overall.

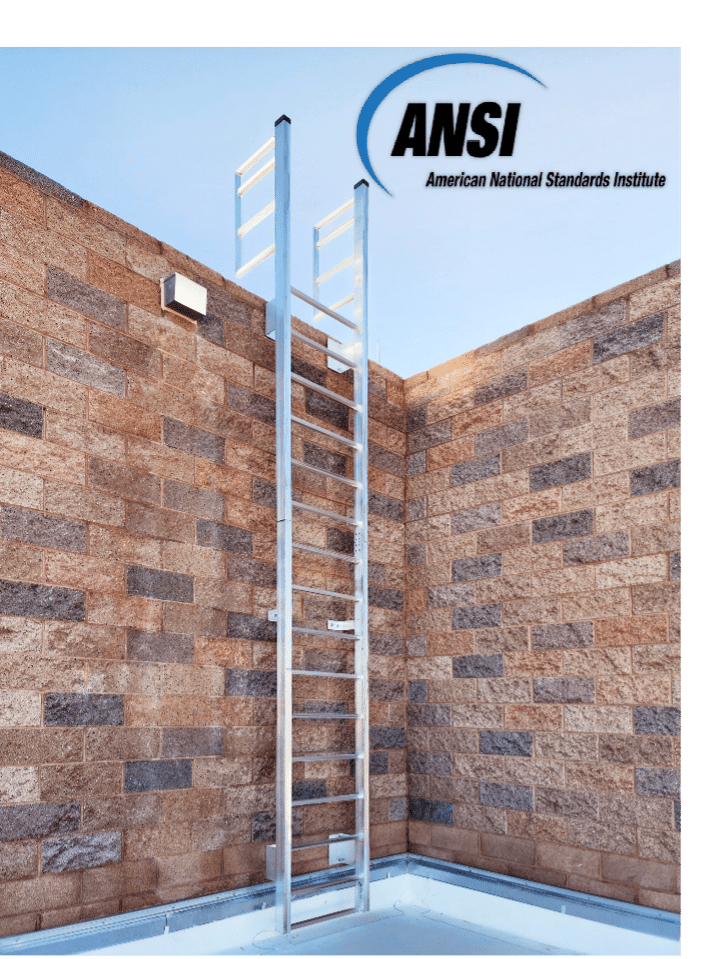

ANSI A14.3-2008: A Comprehensive Standard for Fixed Ladders

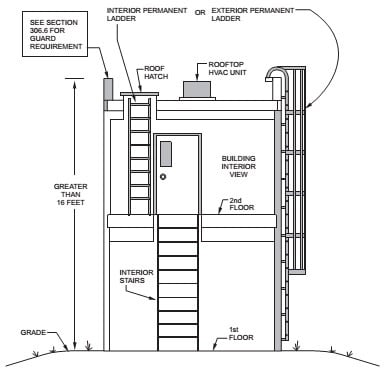

One prominent example of an ANSI standard relevant to workplace safety is ANSI A14.3-2008, titled “American National Standard for Ladders-Fixed-Safety Requirements.” This standard provides detailed safety requirements specifically for fixed ladders, addressing dimensional specifications and design considerations crucial for ladder specifier and building designers alike.

Key Dimensional Requirements from ANSI A14.3-2008

Here are some key dimensional requirements outlined in ANSI A14.3-2008:

- Rung and Step Spacing:

- The first rung’s spacing from the ground should be within 14 inches (35 cm), with subsequent vertical spacing between rungs set at 12 inches (30 cm).

- Minimum inside clear width of step surfaces should be 16 inches (40 cm).

- Side Rails:

- Side rails on through or side-step ladders must extend at least 3 feet 6 inches (106 cm) above the top of the access or landing platform.

- For through ladder extensions, side rails should be flared to provide clearance between 24 inches (60 cm) and 30 inches (76 cm).

- Extension and Grab Bars:

- Ladder extensions above access or landing platforms can continue rung spacing horizontally or provide vertical grab bars with the same lateral spacing as rung legs.

- Grab bars must extend at least 3 feet 6 inches (106 cm) above the access or landing platform.

- Clearances:

- A minimum perpendicular distance of 30 inches is required from the centerline of ladder steps or rungs to the nearest permanent object on the climbing side.

- Clearance to the nearest permanent object behind the ladder should be no less than 7 inches (18 cm).

- Step-Across Distance:

- Sidestep ladders at access points to platforms should provide a step-across distance between 15 inches (38 cm) minimum and 20 inches (50 cm) maximum from the ladder’s centerline.

Enhancing Safety through Compliance

By integrating ANSI standards into workplace safety protocols, employers demonstrate a commitment to maintaining high safety standards beyond basic regulatory requirements. Designing and implementing structures and equipment in accordance with ANSI standards not only mitigates risks but also contributes to a safer and more efficient work environment. Moreover, aligning with the most stringent standards—whether OSHA-mandated or ANSI-recommended—ensures comprehensive protection for workers and reduces the likelihood of workplace incidents.

In conclusion, while OSHA sets the legal framework for workplace safety, ANSI standards provide essential voluntary guidelines that complement regulatory requirements. Embracing both ensures a holistic approach to safety management, fostering a workplace culture focused on the well-being and security of all employees. By staying informed and implementing these standards, companies uphold their responsibility to create safer working conditions and promote sustainable operational practices.

Recent Comments