The Benefits of Using Aluminum Fixed Ladders vs Steel Ladders in Commercial Construction

Construction is not an easy job. Every day, you’re expected to pull off tiresome work that can be dangerous sometimes. Even if your official designation in a project leans more on the management side, the bulk of your responsibility cannot be overstated. After all, your duties span the timely progress of the project, precision of completed tasks, and safety of workers.

Choosing the best construction tools is one way to ensure that those three goals are met. However, it proves most crucial to workers’ safety.

When deciding among the wide variety of fixed ladders available in the market, do not cut corners. Always go for the best option possible. Remember that about 300 ladder-related deaths happen each year in the United States alone.

You do not want your construction project to contribute to that alarming statistic. With that said, here are the reasons why aluminum ladders are preferred for commercial construction.

1. Rust and corrosion-resistant

Aluminum resists rust and corrosion naturally. That makes the material suited to ladder design. And even more suited to commercial construction where outdoor ladders are common. If the construction site has no indoor storage, the more beneficial aluminum ladders become.

That’s because you’re assured they won’t deteriorate due to exposure to natural elements such as the sun, wind, rain, and humidity. There’s no need to worry about ladder rungs breaking under the weight of workers.

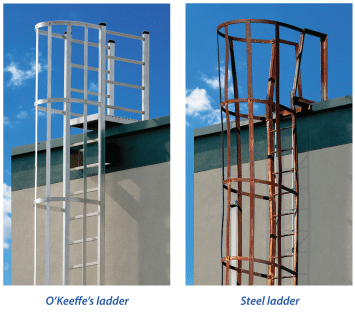

Meanwhile, steel ladders are prone to rust and corrosion that compromise ladder stability and durability. That makes them unsafe for constant outdoor use, such as in commercial construction.

2. Low lifetime cost

For steel ladders to become as rust and corrosion resistant as aluminum ladders, they must be galvanized or made from stainless steel. Considering the customization costs, these make steel ladders more expensive. On the other hand, aluminum ladders are more affordable, which is precisely why they are popular even in households.

On top of shelling out less than what you would for a steel ladder, aluminum ladders are low maintenance, too. You can reuse aluminum ladders for multiple commercial construction projects without breaking the bank.

3. Environmentally friendly

You contribute to the well-being of Mother Nature when you opt for aluminum ladders. That’s because aluminum is a sustainable building material that is 100% recyclable. Even more interesting, it can be recycled again and again without losing its inherent qualities. In fact, nearly 75% of aluminum ever produced still circulates today, thanks to recycling.

The construction industry accounts for 38% of carbon emissions. As a stakeholder in the industry, this figure is something you should keep in mind. All things considered, going aluminum for your building ladders will undoubtedly be a green choice.

4. Lightweight and high-strength

Workers transporting heavy objects from one place to another is a common sight in construction sites. Given that steel ladders can be heavy, moving them constantly is downright impractical and difficult for workers.

Aluminum ladders, on the other hand, are lightweight. But that does not mean they’re not strong enough to support the weight of your bulkiest worker. Aluminum boasts an excellent strength-to-weight ratio

5. Maximum foot traction

Construction workers typically move fast, even when climbing ladders. To keep them safe, the ladders need to have rungs that allow maximum foot traction. That’s what you get with aluminum ladders. Or you can have custom ladders made with rungs to your liking. As for steel ladders, the rungs are usually round and not serrated, making them prone to slippage.

6. Non-spark and non-magnetic

Construction sites need to prioritize tools and materials that are not fire hazards. Aluminum ladders won’t spark even when struck against each other, or with other non-ferrous metals. They are also non-magnetic, which means they can be used even in construction sites that employ magnetic equipment.

7. Multiple finishes

Aluminum ladders offer a variety of finishes. The two main categories are clear and anodized. For the latter, you have clear, bronze, and black anodized, among others. Anodized finish does not apply to steel, leaving you with limited options.

Ladder Up

It’s high time you level up when it comes to how you run your commercial construction project. Begin with top-notch tools. Choose fixed aluminum ladders. They boast safety and durability, and that’s the winning combo you need.

For your ladder needs, look no further. Here at O’Keeffe’s, we assure you of products compliant with the Occupational Safety and Health Administration (OSHA) and American National Standards Institute (ANSI) regulations. Plus, our custom ladders will suit whatever needs and preferences you may have.

Get in touch with us today to know more. We will be glad to serve you.